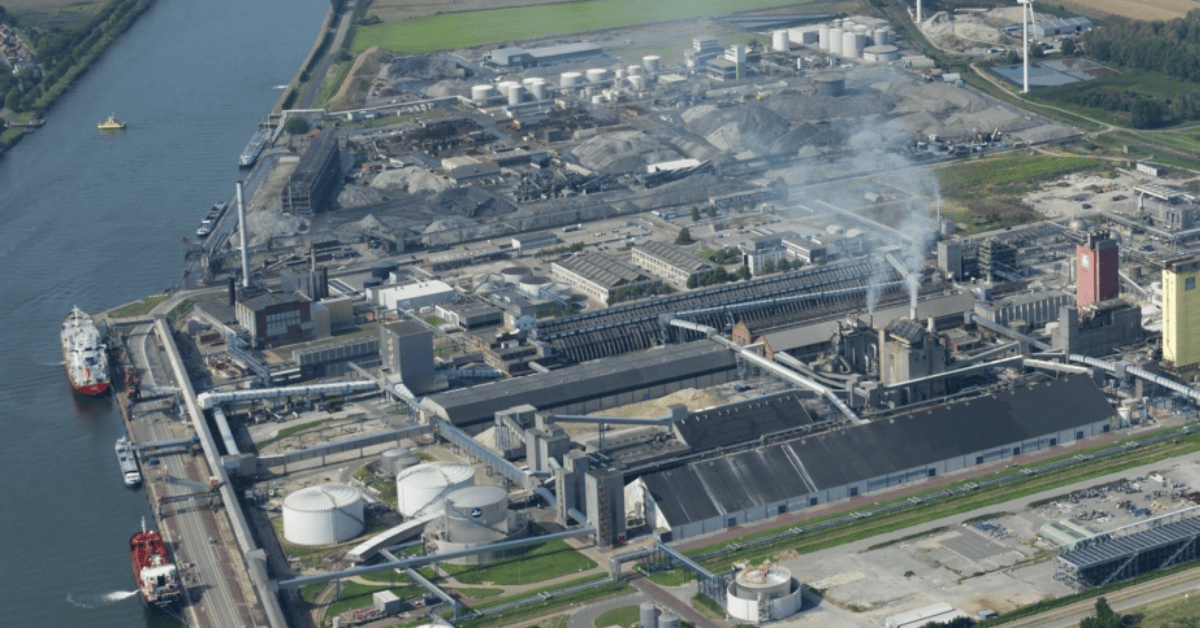

When a German specialist insulation contractor secured work at Yara’s Sluiskil site, Fullspec led the HSE mobilisation effort — ensuring a safe and on-time start under Dutch Tier 1 standards.”

Learn more about how Fullspec supports HSE mobilisation and system integration projects across Europe

For NEMA GmbH, success depended on translating existing German internal safety practices into full alignment with YARA’s Dutch Compliance Framework — across languages, regulations, and expectations. That’s where Fullspec stepped in.

The Challenge: Cross-Border Mobilisation Under Tier 1 Standards

Mobilising for a project at YARA Sluiskil meant more than preparing a few standard safety documents. The process involved:

- Understanding and applying YARA’s HES Construction Plan and Construction Requirements

- Integrating German company systems into Dutch regulatory frameworks

- Managing tight pre-start timelines

- Coordinating between client, site management, and multiple subcontractor interfaces

In short, the goal was simple — a fully compliant, ready-to-start operation — but the path required precision and structure.

Fullspec’s Role: From Documentation to Deployment

Fullspec was engaged to lead the HSE mobilisation effort from planning to on-site readiness. The scope included:

- Pre-Mobilisation Documentation: Development and alignment of project-specific HSE Plans, Method Statements, and supporting registers in accordance with YARA’s HES documentation structure.

- Client Documentation Review: Detailed cross-check of YARA’s HES requirements, ensuring every submission met the relevant clauses of the Construction Plan and Appendices.

- Local Legal Compliance Assessment: Verification of all Dutch occupational safety and environmental requirements applicable to insulation activities and chemical handling — including alignment with GefStoffV, TRGS 510/900, and Dutch Arbowet obligations.

- Client Interface and Site Visits: Direct engagement with YARA’s HSE management to clarify requirements, confirm documentation acceptance, and align on mobilisation sequencing.

- Local HSE Resource Mobilisation: Identification and onboarding of a qualified local HSE officer to provide continuous on-site presence, ensuring smooth start-up and immediate compliance.

The Outcome: A Safe, Seamless Start

Through structured planning and clear communication, Fullspec enabled NEMA GmbH to:

- Achieve full client approval for all HSE documentation before start-up

- Mobilise to site on schedule, with no delays or documentation holds

- Begin work safely, with verified local compliance and a competent HSE resource on the ground

- Establish a repeatable mobilisation framework for future European projects

Reflections: The Start Sets the Standard

In complex industrial environments, the start of a project, can often determine its outcome.

Mobilisation isn’t just paperwork — it’s the moment where systems become practice, and preparation becomes performance.

At Fullspec, our role is to make that transition seamless — bridging regulations, languages, and expectations so that contractors can focus on delivering their work safely, confidently, and on time.

Planning to mobilise for a complex or cross-border project?

Fullspec helps contractors bridge the gap between internal systems and client expectations — so mobilisation runs smoothly, safely, and on time.

Get in touch to see how we can support your next project start-up.